The Fundamentals of Milling Technology Part I

By: Ron Dietz

Milling machining is the most versatile and the most common of all the machining processes. It is not a machine shop without a least one of the many type of mills in it. The history and versatility of this manufacturing process cannot be thoroughly discussed in one article-it will take many to discuss all of the aspects of the function, tooling, and operation of this remarkable technology. This first article on milling tooling will discuss the actual mechanics of the removal process with the cutting tool.

THE CUTTING PROCESS:

Milling is a material removing process. Using multiple edge rotating cutting tools-material is removed as the work is fed into the cutters at a certain velocity or feed rate. For basic 2-D vertical milling the material is fed into the cutters at right angles to the center line of the cutting tool.

Vertical Milling Process

THE CUTTING ACTION:

The actual removal of the material is from the cutting edge shearing the material away in a complex process. As the edge of the tool comes into contact with the material-shearing action removes a “chip” of material:

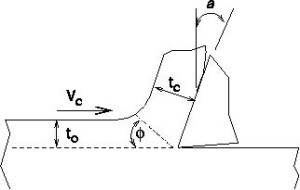

Chip thickness depends on the shear angle the shear plane makes with the work piece:

to = non-deformed chip thickness or depth of cut

tc = chip thickness

Φ = shear angle

Vc = Feed rate

a = rake angle of tool

In this model the shear plane angle can be determined by the equation:

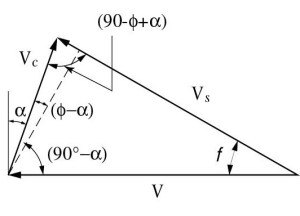

r = to/tc = sin Φ/cos (Φ-a)

Because the depth of cut can be chosen, the chip thickness can be measured, and the rake angle can be chosen or measured-the shear angle can be determined. Why does anyone care? Because the shear angle directly influences a whole bunch of parameters such as: cutting forces, machine power, cutting temperature, and chip thickness-to name a few.

It is also influences the shear strain:

γ = cot Φ + tan (Φ – α)

As can be seen-the shear plane angle is an important parameter in the mechanics of machining theory. We can use this parameter to continue the analysis-and look at velocity of the strain (strain-rate). In the next post we will look at the these velocities and the cutting forces that are developed during the cutting process.

Please feel free to comment on the above post. I realize that there is a lot left out and a lot that could be said. However, this is just an overview of the processes and not a dynamics magazine. If you think there should have been anything added or I did not explain something right-please comment. This magazine is about learning and exploring technical/complex subjects-I encourage discussions. Please register and log in to comment.

References:

Every text, webpage, blog, or book that discusses the mechanics of machining. In other words-this is commonly available knowledge.

Ron Dietz is the Editor-in-Chief for Tooling Magazine.

He has a BS in Mechanical Engineering and an MS in Engineering.

He has 18 years experience in metal manufacturing as a welder, machinist, tooling engineer, and machine designer.

His main interests are CNC machine designs, automated machinery, and complex tooling.

FAIR USE NOTICE. This site contains copyrighted material the use of which has not always been specifically authorized by the copyright owner. We are making such material available in our efforts to advance understanding of economic, scientific, and engineering issues, etc.. We believe this constitutes a ‘fair use’ of any such copyrighted material as provided for in section 107 of the US Copyright Law. If you wish to use copyrighted material from this site for purposes of your own that go beyond ‘fair use’, you must obtain permission from the copyright owner.

14 comments

Pingback: acheter générique kamagra en ligne

Pingback: kamagra bez předpisu kanadských předpisů kamagra

Pingback: buy itraconazole online canada

Pingback: how to order fildena generic in united states

Pingback: cheap gabapentin generic uae

Pingback: online order flexeril cyclobenzaprine buy online uk

Pingback: get dutasteride medication interactions

Pingback: how to order avodart generic compare

Pingback: Online staxyn

Pingback: buy xifaxan generic dosage

Pingback: how to order rifaximin cheap sale

Pingback: buy cheap enclomiphene generic online uk

Pingback: how to buy androxal generic from the uk

Pingback: MyBlog