Machining Castings

By: Ron Dietz

Machining castings is one of the more challenging in machining and involves some careful planning. The fixture must be correct or the part can be ruined from just the wrong clamping areas and sequences. The quality of the casting also plays a big role on how well the part will clean up. There are porosity issues that can develop during machining. If the design is wrong-the datum points are removed during machining-and on and on it goes. Let’s look at some of these issues.

Fixtures/Tooling:

Casting tooling must be correctly designed and set-up for successful castings machining. Putting the clamps and supports at the right location is critical to not allow the part to distort, bend in the wrong places, and to have casting features move during machining.

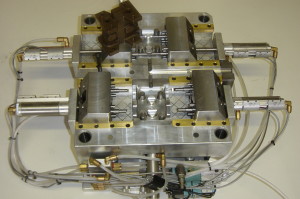

Example of casting tooling-notice using the parts features to help locate-SMC Contract Manufacturing:

http://www.smccontractmfg.com/precision-fixtures-dies.html

Although the fixture plate looks simple it definitely looks like a quality design-the swing clamps are a great way to clamp parts-they provide a quick way to change the part in and out of the fixture.

Cutting Tools:

Cutting tools requirements vary on the type of material that the casting is made out of-and is critical to successful machining of castings for profit. The cutting tools will experience different wear for the various types of steels, cast irons, and aluminum grades that make up the majority of cast parts. There are several competing requirements including:

- the needed toughness for the material being machined;

- high speeds and feed rates capabilities;

- abrasive and adhesive wear resistance based on material properties of workpiece;

These are just a few of the factors to be looked at when machining castings-consulting a high quality tooling company is highly recommended. Even more so if you intend to do high speed-high feed rate machining using a dry cutting scheme.

The Casting Mold:

Some casting molds are “simple” sand castings and some are more complex tooling like in investment castings or lost foam castings. The quality of the tooling has a large effect upon the success of the subsequent machining of the part. This magazine will have many articles dedicated to the different types of casting tooling in future articles. It is safe to say that bad tooling/molding can lead to dimensional issues, porosity of the part, poor datum control, and difficult to clean up surfaces.

Ron Dietz is the Editor-in-Chief for Tooling Magazine.

He has a BS in Mechanical Engineering and an MS in Engineering.

He has 20 years experience in metal manufacturing as a welder, machinist, tooling engineer, and machine designer.

His main interests are CNC machine designs, automated machinery, and complex tooling.

FAIR USE NOTICE. This site contains copyrighted material the use of which has not always been specifically authorized by the copyright owner. We are making such material available in our efforts to advance understanding of economic, scientific, and engineering issues, etc.. We believe this constitutes a ‘fair use’ of any such copyrighted material as provided for in section 107 of the US Copyright Law. If you wish to use copyrighted material from this site for purposes of your own that go beyond ‘fair use’, you must obtain permission from the copyright owner.

13 comments

Pingback: kde koupit kamagra singapore

Pingback: buying rifaximin cost without insurance

Pingback: cheapest buy xifaxan purchase prescription

Pingback: how to order avodart without rx online

Pingback: cheap itraconazole canada low cost

Pingback: Where to buy generic staxyn online without a perscription

Pingback: discount fildena buy adelaide

Pingback: discount gabapentin lowest price viagra

Pingback: online order dutasteride lowest price viagra

Pingback: get flexeril cyclobenzaprine buy from canada

Pingback: cheap androxal without a script

Pingback: purchase enclomiphene cheap trusted

Pingback: medicament kamagra pharmacie livrer a domicile de medicaments